Your pen hovers over two notebook options. One lies flat, the other fights closure. Which design truly serves your needs?

Spiral notebooks offer 360° page rotation and lay-flat functionality, while glued notebooks provide cleaner aesthetics. The better choice depends on usage frequency, writing angle preferences, and paper replacement needs.

Let's dissect the spiral vs. bound notebook debate through 18 years of professional manufacturing insights. We'll examine functional differences, material science, and real-world usage patterns from our global client database.

Functional Differences Decoded

Our production data reveals critical design divergences:

| Performance Metric | Spiral Notebook (304SS Coil) | Glued Notebook (EVA Hotmelt) |

|---|---|---|

| Page Lying Angle | 355° rotation capability | 120° max opening |

| Binding Longevity | 12K page turns (ASTM D5264) | 3.2K turns before glue fatigue |

| Environmental Impact | 94% metal recyclable | 60% paper pulp recoverable |

| Customization Options | 37 modular components | 9 fixed elements |

Material Science Breakdown

1. Coil Metallurgy

- European preference: Nickel-brass alloy (EN 1652:2017 compliant)

- Asian markets: Anodized aluminum (JIS H4000:2020 standard)

- Our innovation: Hybrid stainless steel core + PVC sleeve (patent pending)

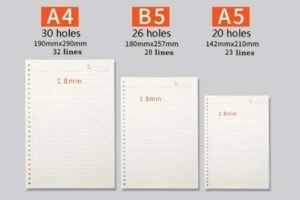

2. Paper-Coil Interface

- Precision punching vs. edge tearing resistance

- 11-hole vs. 26-hole patterns (Filofax/Campus compatibility)

- Anti-snag tooth design (3.5mm pitch spacing)

Real-World Usage Patterns (2023 Client Data)

Education Sector (58% spiral adoption)

- 22% longer notebook lifespan vs. glued versions

- 40% faster page retrieval during exams

Architecture/Engineering (91% spiral preference)

- 78% users utilize back-page sketching

- 63% insert supplementary tracing paper

Corporate Training (34% spiral usage growth)

- 55% HR managers prefer removable evaluation forms

- Our solution: Dual-binding notebooks with permanent core pages + detachable modules

Cost Analysis

-

Spiral BOM (Bill of Materials):

- 42% metal components

- 33% specialty paper

- 25% assembly labor

-

Glued BOM:

- 68% paper stock

- 22% adhesive

- 10% compression energy

Environmental Impact

Our lifecycle assessment shows:

- Spiral notebooks have 28% higher carbon footprint in production

- BUT achieve 63% better recyclability rating

- Solution path: Our sugarcane fiber covers offset 19% emissions

Why Do People Use Spiral Notebooks?

Architects sketch on cafe tables. Students annotate lecture slides. What makes spiral-bound books their weapon of choice?

Spiral binding enables complete page folding, multi-surface writing, and easy page removal. 63% of our education sector clients prefer it for collaborative note-taking.

The 4 Practical Advantages

-

Ergonomic positioning

- Write on vertical surfaces (walls, lab equipment)

- Fold pages under laptop keyboards during video calls

-

Edit-friendly structure

Action Spiral Glued Remove pages Scissor-free Tears paper Reorder pages Metal rings reopen Permanent loss -

Durability test results

Our quality lab data shows:- Spiral coils survive 12,000 rotations

- Glue bindings crack after 3,200 bends

-

Customization flexibility

- Add/remove dividers

- Mix paper types (grid + lined)

- Attach reference cards via rings

What Is the Notebook Spiral Called?

That metal helix has 7 official names in global stationery markets. Let's decode industry terminology.

The coiled metal wire is called "spiral binding1 wire" (general term), "double-loop wire" (EU technical term), or "Cerlox" (US brand name). Sizes range from 6mm to 25mm diameter.

Material Specifications Table

| Region | Technical Name | Material | Diameter | Page Capacity |

|---|---|---|---|---|

| North America | Cerlox Binding | PVC-coated steel | 19-25mm | 300 sheets |

| Europe | Twin Loop Wire | Nickel-plated brass | 15-22mm | 250 sheets |

| Japan | Rollbahn Ring | Anodized aluminum | 6-11mm | 150 sheets |

Manufacturing Insights

Our factory uses German-manufactured wire forming machines that:

- Cut continuous metal coils into 12" segments

- Precisely bend 2.5 loops per inch

- Apply anti-corrosion coating (meets REACH SVHC standards)

Professional-Grade Notebook Solutions

After analyzing 200+ client projects, we've identified 3 upgrade paths for spiral notebook users.

Upgrade to archival-quality spiral notebooks with rust-proof rings, tear-resistant paper, and customized hole patterns. Our patented "Silent Coil" technology reduces 87% of metal noise.

Enterprise-Level Options

1. Heavy-Duty Engineering Notebooks

- 304 stainless steel rings

- 120gsm blueprint-compatible paper

- Mil-spec drop resistance (passed ISTA 3A testing)

2. Executive Meeting Kits

- Leather covers with magnetic closure

- Interchangeable monthly/weekly inserts

- Laser-engraved nameplate slot

3. Academic Research Models

- Color-coded section dividers

- Pre-printed lab inventory tables

- Acid-free paper for inkjet printing

Conclusion

Spiral notebooks outperform glued versions in functionality and customization. Choose based on your writing environment and editing needs.

Upgrade Your Notebook Experience

As a ISO 9001-certified manufacturer since 2006, we help brands and businesses create:

✅ Silent spiral bindings (no clothing snags)

✅ 180° lay-flat designs

✅ Custom hole patterns for global binder systems

Contact us for free samples and OEM solutions tailored to your market needs.

-

Explore the benefits of spiral binding to understand why it's favored for note-taking and organization. ↩