Struggling to picture how those handy spiral notebooks are actually made? The whole manufacturing process might seem quite complex, especially for large quantities. As someone who's been in this business since 2006, I'm here to break down the steps in a simple way.

Making a spiral notebook involves printing the inner pages and covers, precisely punching holes along one edge, collating the components in the correct order, and then inserting and closing a spiral binding1 element (like metal Wire-O or plastic coil) through those holes.

This basic description gives you the idea, but professional production requires more. We need to select the right materials first. Think about the paper weight and the cover stock. Then, specialized machinery comes into play for printing, punching, and binding. Quality control is also essential at every single step. This ensures the final notebook is not just functional but also durable and meets your standards.

Let's look closer at these stages. For example, the printing stage uses high-speed presses. Punching needs absolute precision so pages turn smoothly. Binding machines carefully insert the wire or coil and crimp it closed. Each part of the process builds on the last one to create the notebook you hold in your hand. It's a blend of material science and mechanical precision that we've refined over 18 years.

What Materials Are Needed for Spiral Notebook Production?

Now that you understand the basic flow, let's talk about the core components. What exactly goes into making a spiral notebook?

The essential materials for a spiral notebook are paper for the inner pages, a sturdier material for the front and back covers (like cardstock, plastic, or specialized boards), and the spiral binding itself, which is usually metal Wire-O or a plastic coil.

Choosing the right materials is critical for the final product's look, feel, and durability. Let's dive deeper into these components:

Paper Selection

The heart of any notebook is its paper.

- Weight: Common choices range from 80gsm to 120gsm. We often use 80gsm as standard, but upgrading to 100gsm adds a more premium feel for a small cost increase (around $0.07/book). Thicker paper reduces ink bleed-through.

- Type: Options include versatile acid-free paper (great for longevity), eco-friendly recycled paper (we offer this at no extra charge), or premium options like smooth Japanese Tomoe River paper or European sketch paper for specific needs.

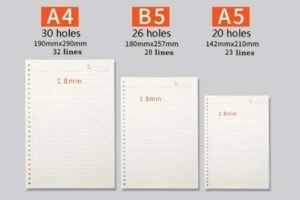

- Format: You can choose standard rulings like horizontal lines, grids, or dots. Blank pages are also an option. We can also add features like page numbers or rounded corners.

Cover Materials

The cover protects the pages and provides the main visual appeal.

- Standard Options: Thick cardstock is common. We also offer durable and flexible PP plastic covers, sometimes using degradable options.

- Premium & Eco Options: For a more sophisticated look, cloth hardcovers are available. We also explore sustainable materials like covers made from bagasse fiber (a sugarcane byproduct).

- Custom Finishes: This is where you can add branding. We offer hot stamping (adds about $0.08/unit), laser engraving ($0.12/unit), or embossing/debossing ($0.15/unit) for logos and designs.

Spiral Binding

This holds everything together.

- Type: Metal Wire-O binding is very popular for its professional look and ability to lay flat or fold back 360 degrees. We use high-quality 304 stainless steel for durability and apply rust-proof electroplating. Plastic coils are another flexible and often more budget-friendly option.

- Our Innovation: We developed a patented "seamless coil" technology for metal binding. This ensures a completely smooth 360° touch, preventing snags on clothes or bags.

What Are the Key Steps in the Manufacturing Process?

We have the materials ready. So, how do we combine them into a finished spiral notebook?

The key manufacturing steps, in order, are: designing and printing the inner pages and covers, collating these printed components, precisely punching the binding holes, inserting the spiral coil or wire, securely closing the binding, and performing final trimming and quality checks.

Executing these steps efficiently and accurately requires expertise and the right equipment. Here’s a closer look at each stage in our factory:

1. Design and Printing

It starts with your design. Once artwork for covers and inner pages is finalized, it goes to pre-press. We check everything carefully. Then, printing begins. We use advanced machines like German Heidelberg glue binders (for other binding types) and high-speed presses for accurate color reproduction and sharp lines on the paper you selected.

2. Collation

After printing, the large sheets are cut down to the notebook size. Then, the inner pages and the front and back covers are gathered in the correct sequence. This has to be done accurately for every single notebook.

3. Punching

This step creates the holes for the binding. Precision is key. The holes must line up perfectly from the first page to the last. Misaligned holes make page-turning difficult. Our specialized punching machines ensure uniformity across the entire batch, matching standard hole patterns if needed (like for 6-hole or 26-hole systems).

4. Binding

Here, the collated and punched pages and covers meet the spiral element. The Wire-O or plastic coil is inserted through the holes. For Wire-O, a machine then carefully closes the wire loops to create a secure seam. Our seamless coil process adds an extra touch of quality here.

5. Finishing and Quality Control (QC)

Finally, the notebooks might get a final trim for perfectly smooth edges. Then comes our rigorous quality control2. We don't just glance at the finished product. We have a 4-level inspection process:

| QC Check | Detail | Standard Met |

|---|---|---|

| Paper Weight & Opacity | Verify gsm and light transmittance | ±3% tolerance |

| Binding Strength | Test durability under repeated page turns | ≥500 page turns |

| Metal Parts Corrosion | Salt spray test on metal bindings | 48 hours, no rust |

| Finished Product Safety | Drop and transport simulation tests | ISTA 3A standard |

This multi-level check ensures every batch meets high standards for usability and durability.

How Can You Customize Your Spiral Notebooks?

A standard spiral notebook is useful, but customization3 makes it truly yours. How much can you actually change?

You can customize almost every aspect of a spiral notebook: select unique cover materials and add branding via hot stamping or laser engraving, choose specific paper types and print custom inner page layouts, pick different binding types and colors, and even add accessories or request special sizes.

Customization is where we really shine, helping clients create notebooks perfectly suited to their needs. Let's explore the possibilities:

Cover Customization Options

- Material Choice: Go beyond standard cardstock with options like textured paper, durable PP plastic (including degradable versions), elegant cloth hardcover, or unique eco-friendly materials like bagasse fiber.

- Branding & Finishes: Make your mark with sharp hot stamping (great for metallic foils), subtle embossing/debossing for a tactile effect, or precise laser engraving, especially on metal or certain cover types. These small additions significantly elevate the perceived value.

Inner Page Selection

- Paper Details: Choose the exact paper weight (80-120gsm) and type (acid-free, recycled, premium Japanese paper) for your purpose.

- Layout Design: We can print standard rulings (lines, grids, dots) or fully custom layouts. Think planner pages, project logs, branded footers, page numbers, or even perforated sections for easy tearing. Corner rounding adds a soft touch.

Binding Choices

- Style & Color: Select classic metal Wire-O in various colors (silver, black, gold, custom colors) or flexible plastic coils.

- Compatibility: We can ensure hole punching matches international standards like Filofax (6-hole) or Kokuyo Campus (20/26-hole), so your notebooks fit existing systems.

Additional Features & Sizes

- Beyond Standard Sizes: While A5 is popular, we produce notebooks in various sizes like B6, passport size, or completely custom dimensions.

- Accessories: Consider adding elastic closures, ribbon bookmarks, or internal pockets for extra functionality.

- Special Processes: We can handle unique requirements like the special die-cutting needed for shaped notebooks or the pre-cut dotted lines we developed for a Japanese client's washi tape notebook.

Why Choose NotebookRing® for Your Spiral Notebook Needs?

Understanding how spiral notebooks are made highlights the importance of partnering with a capable manufacturer. With so many options out there, why should you consider working with us at NotebookRing®?

Since 2006, we've focused solely on manufacturing high-quality paper stationery. This 18-year dedication means we have deep expertise in materials, processes, and quality control. Our 15,000㎡ factory is FSC™ and BSCI certified, equipped with 8 production lines including top-tier German and Japanese machinery.

Here's what sets us apart:

- Vertical Integration: We manage the process from raw materials (operating our own special paper processing and metal stamping workshops) to the finished product. This gives us greater control over quality and lead times.

- Flexible Customization: We understand not everyone needs huge quantities. We support sample orders starting from 100 units for basic versions and full production runs from 500 units, accommodating businesses of various sizes like James Wong's gifting company needing 300 sets/month.

- Commitment to Quality: Our 4-level QC system (covering paper, binding, metal parts, and transport simulation) ensures reliability. We meet ISO 9001 standards and chemical safety requirements like REACH/SVHC.

- Innovation: We continuously refine our craft, like our patented "seamless coil" technology for a snag-free finish.

- Eco-Conscious Production: We hold FSC™ certification (C106904), offer recycled paper, use soy ink, provide bagasse fiber covers, and even donate a sapling for every 100 books sold. This helped us meet the needs of clients like Sarah Müller's German chain requiring EU Ecolabel standards.

- Global Reach & Logistics: We export globally (60% to Europe/USA, 25% to Japan/Korea) and offer reliable 30-day standard delivery, with expedited options available. We support various trade terms (EXW/FOB/DDP) and can manage inventory through bonded warehouses.

Our experience ranges from producing over 120,000 FSC-certified notebooks annually for a German bookstore chain to developing unique onboarding kits for Silicon Valley tech companies, reducing their costs by 32%.

Conclusion: The Summary for the Whole Post.

Making a spiral notebook involves careful material selection, precise printing, punching, binding, and rigorous quality checks. Customization options are extensive, and partnering with an experienced manufacturer like NotebookRing® ensures a high-quality, tailored result that meets your specific needs.

-

Explore this link to understand the significance of spiral binding in notebook manufacturing and its advantages for durability and usability. ↩

-

Learn about effective quality control measures in notebook production to ensure high standards and customer satisfaction. ↩

-

Discover the endless possibilities of customizing spiral notebooks to suit your personal or business needs, enhancing both functionality and aesthetics. ↩