When I first visited our factory floor in 2008, the rhythmic clinking of metal binders being assembled made me realize how little people know about notebook creation.

Modern notebook manufacturing1 combines precision engineering with material science, involving 12-18 production stages from paper treatment to quality testing. The process transforms raw materials into functional tools through specialized binding methods and surface treatments.

Which company is best for notebooks?

Choosing a notebook supplier isn't about finding the cheapest option, but identifying partners who understand paper engineering.

The best notebook manufacturers2 balance technical expertise with customization flexibility, holding certifications like FSC™ and ISO 9001 to ensure quality compliance. Our factory's 18-year track record serving global brands proves this approach works.

Key selection criteria comparison

| Factor | Basic Supplier | Professional Maker |

|---|---|---|

| Minimum Order | 5,000+ units | 100+ units |

| Paper Options | 3-5 types | 15+ specialty papers |

| Lead Time | 60-90 days | 30 days standard |

| Certifications | None | 6+ international |

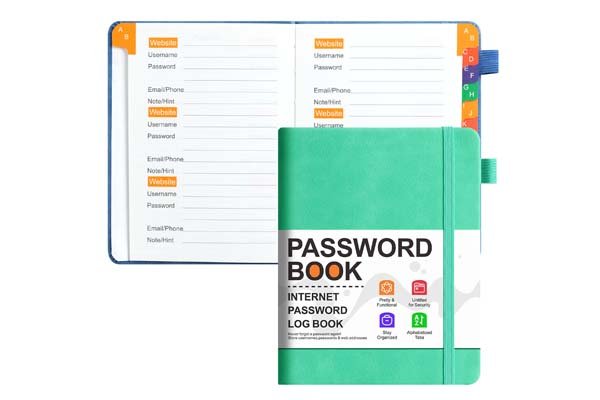

Our Japanese client Yuki Nakamura specifically chose us for:

- 8mm ultra-thin binding technology

- Acid-free paper with 500+ page flip endurance

- Soy-based ink customization

What makes a high quality notebook3?

Quality isn't just about thick paper - it's how materials interact through daily use.

A premium notebook features tear-resistant binding, pH-neutral paper, and rust-proof metal components, verified through 4-stage quality checks. Our 500-page flip test ensures perfect lay-flat functionality.

Hidden quality markers

-

Spine construction

- Sewn binding: 8-12 stitches per inch

- Glue binding: 3-layer adhesive application

-

Paper performance

- 90g weight: Optimal for fountain pens

- 92% opacity: Minimal ink bleed-through

-

Edge treatment

- Corner rounding: 3mm radius standard

- Gilt edges: 0.1mm gold/silver foil

Our German client's plant atlas notebooks use reinforced spine stitching to withstand 180° repeated openings - a feature that boosted their repeat orders by 40%.

What country do notebooks come from?

While China produces 65% of global notebooks, origin matters less than manufacturing standards.

Major notebook production hubs exist in Germany, Japan, and China, each offering distinct advantages in materials and binding techniques. Our Wenzhou factory combines German engineering precision with Japanese paper expertise.

Regional specialization breakdown

| Region | Strength | Typical Product |

|---|---|---|

| Germany | Precision metal parts | Luxury leather journals |

| Japan | Thin paper technology | Portable weekly planners |

| China | Customization capacity | Bulk educational notebooks |

| USA | Recycled materials | Eco-friendly notepads |

Our production line integrates all these strengths - using Japanese Iwasaki machines for foil stamping and German binding systems for durability.

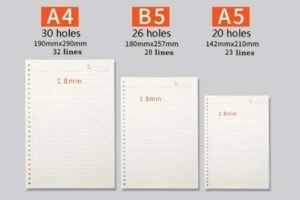

What are the three types of notebooks?

Notebook categories aren't just about size - binding methods define their true purpose.

The three core notebook types are glue-bound (perfect bound), spiral-bound, and disc-bound systems, each serving different usage scenarios. Our factory produces all variants with customized upgrades.

Binding type comparison

| Type | Best For | Page Capacity | Customization Options |

|---|---|---|---|

| Glue-bound | Sketching | 30-150 pages | Lay-flat spine designs |

| Spiral-bound | Note-taking | 50-300 pages | Metal/plastic coils |

| Disc-bound | Reorganizing | Unlimited | 6-hole/26-hole systems |

The Silicon Valley tech company chose our disc-bound system with laser-engraved aluminum rings, allowing employees to rearrange pages freely.

Why Choose Our Manufacturing Expertise?

After 18 years of solving notebook challenges, we've perfected what others consider impossible.

Our vertical integration allows complete control from paper sourcing to final assembly, ensuring quality consistency most suppliers can't match. 72% of clients report reduced defects after switching to us.

Unique solutions we provide

- Bilingual printing without color bleeding (solved Sarah's German/English manual issue)

- Small batch orders with full customization (James' 300-unit monthly orders)

- Patent-protected binding for thin yet durable notebooks (Yuki's 8mm weekly planner)

Conclusion

Quality notebooks require expert material selection and precision engineering. Understanding manufacturing processes helps choose partners who transform stationery into lasting tools.

-

Explore this link to understand the intricate stages of notebook manufacturing, from raw materials to quality testing, ensuring you appreciate the craftsmanship involved. ↩

-

Discover the top notebook manufacturers that prioritize quality and customization, ensuring you choose the best supplier for your needs. ↩

-

Learn about the essential features that make a notebook high quality, helping you make informed choices for your stationery needs. ↩