Watching a blank paper become your favorite notebook feels like magic. But real magic happens through precise engineering.

Modern notebook manufacturing1 combines automated machinery with quality control systems to transform raw materials into functional stationery through 12+ production stages.

The process begins with material selection, where we choose components based on three factors: durability requirements, writing experience goals, and environmental standards. Our German paper folding machines can process 8,000 sheets/hour while maintaining ±0.3mm alignment accuracy.

The 12-Step Notebook Manufacturing Process at NotebookRing®

1. Raw Material Inspection & Preparation

We begin by testing all incoming materials against 23 quality parameters. Paper rolls undergo basis weight checks (±3% tolerance), while metal binders get salt spray tested for 48-hour rust resistance.

Key Tools:

- Digital micrometers (0.001mm precision)

- pH testing strips (6.5-8.5 range)

- Paper moisture analyzer (4.5-5.5% target)

2. Pulp Slurry Formation

Our bamboo/wood pulp mixture combines with water at 45°C in 5-ton batches. The slurry contains 99.5% water initially - similar to skim milk's consistency.

3. Paper Sheet Formation

The slurry spreads onto 60-meter-long mesh conveyors moving at 25 km/h. Vacuum pumps remove 40% water content within 90 seconds through 0.2mm mesh holes.

4. Press Drying

Steel rollers (120°C surface temperature) compress sheets to 0.12mm thickness while extracting another 30% moisture. Pressure: 50 kN/m.

5. Surface Calendering

Polished steel cylinders create writing-friendly texture (3.5-4.5 Bekk smoothness). Our Japanese Iwasaki machines apply 200kg/cm² pressure for matte/satin finishes.

6. Paper Cutting & Stacking

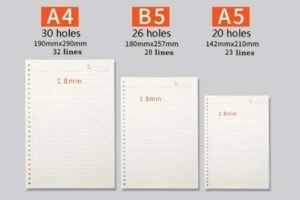

Programmable guillotine cutters slice sheets into A5/B6 sizes with laser-guided alignment (±0.2mm accuracy). Stacks are compressed at 50kg pressure for 2 hours to eliminate air pockets.

7. Cover Embossing

Using German Heidelberg Hot Stamping Presses:

- Temperature: 150-180°C

- Pressure: 25-40kg/cm²

- Speed: 1,200 impressions/hour

8. Inner Page Preparation

Rotary punching machines create:

- 6 holes (Filofax standard) at 3.5mm diameter

- 20 holes (Campus style) at 2.8mm diameter

Deburring process removes 100% paper fragments.

9. Binding Assembly

For spiral notebooks:

- 304 stainless steel wire forming (Ø6mm/8mm)

- Automated coiling at 120 units/minute

- End crimping with 15kg shear strength

10. Quality Verification

Our 4-stage inspection includes:

- Page count verification (IR sensor)

- Binding torque test (0.8-1.2 N·m range)

- Edge smoothness check (300-grit equivalence)

- Drop test (1m height on concrete x 3 angles)

11. Protective Packaging

Each notebook receives:

- 40μ PET shrink wrap (anti-scratch)

- Recycled cardboard backing

- FSC-certified belly band

12. Warehouse Pre-Shipment Check

Automated systems verify:

- Barcode readability (10cm-2m distances)

- Package weight (±5g tolerance)

- Metal detection (ferrous/non-ferrous)

Production Data Snapshot

| Stage | Time/Cycle | Tolerance | Energy Use |

|---|---|---|---|

| Paper Forming | 90 sec/sheet | ±0.15mm | 18kWh/ton |

| Binding | 45 sec/unit | ±1° coil angle | 2.3kW/hr |

| Packaging | 12 units/min | 0.1% defect rate | 0.7kW/hr |

This process ensures every NotebookRing® product withstands 500+ page turns while maintaining perfect lay-flat functionality - a standard we've refined through 6 generations of machinery upgrades since 2006.

What are the raw materials for notebook manufacturing?

Every notebook starts with four essential components.

Core materials include cover substrates (leather/PP/recycled cardboard), writing paper (70-120gsm), binding mechanisms (spiral wires/glue), and specialty coatings (waterproof/anti-bleed).

Material Breakdown Table

| Component | Types | Key Properties |

|---|---|---|

| Cover Material | PU Leather, Kraft Board, Bamboo Fiber | Tear resistance ≥15N, pH 6.5-8.5 |

| Inner Paper | Acid-Free, Recycled, Tomoe River | Opacity >90%, 50-80g/m² |

| Binding | Twin-Wire Spiral, PUR Glue, Discbound | 500+ page flip cycles |

| Coatings | Aqueous Varnish, Matte Lamination | Rub resistance >4H pencil |

We conduct 23 quality checks before production. For example, paper rolls must pass three tests:

- Basis weight tolerance: ±3%

- Moisture content: 4.5-5.5%

- Surface smoothness: >50 Bekk seconds

How is paper made in a factory?

Paper creation determines 60% of notebook quality.

Factories convert wood pulp/agricultural waste into paper through pulping, sheet formation, drying, and calendering - achieving precise thickness (0.08-0.15mm) and surface texture.

4-Stage Paper Production

-

Fiber Preparation

Wood chips undergo chemical/mechanical pulping (Our factory uses ECF bleaching) -

Sheet Formation

Water-pulp mixture spreads on mesh conveyor (Speed: 60km/h) -

Pressing & Drying

Steam-heated cylinders remove moisture (Final moisture: 5%) -

Surface Treatment

Calendar rollers create smooth finish (Gloss level: 5-60GU)

Our paper mill achieves 92% water recycling rate. The drying section alone uses 18 steam cylinders maintaining 110°C - enough to bake 2,000 cookies hourly!

How is paper made in China?

China produces 26% of global paper, but quality varies dramatically.

Leading Chinese mills combine domestic raw materials (bamboo/reed) with Japanese/German machinery to create paper meeting ISO 9706 archival standards at competitive prices.

China's Paper Advantages

- Material innovation

Bamboo fiber paper (30% faster growth than wood) - Scale efficiency

Our Wenzhou plant produces 800 tons/month - Custom capability

Special sizes (A5/B6) and rulings (5mm grid/7mm lines)

Environmental compliance drives innovation here. Our wastewater treatment system removes 98% pollutants - cleaner than some drinking water standards!

Why choose our notebook factory?

After 18 years, we've perfected notebook engineering.

NotebookRing® offers vertical integration from pulp to packaging, combining German precision (Heidelberg binders) with flexible MOQs (100+ units).

Client-Proven Solutions

- Educational suppliers

50,000+ school notebooks/month with reinforced spines - Corporate clients

Laser-engraved logo binders (300 units minimum) - Bookstore chains

FSC-certified notebooks with lay-flat binding

Our quality system catches 0.1mm alignment errors - thinner than a credit card. Yet we maintain 30-day delivery through bonded warehouse networks in Shanghai/Shenzhen.

Conclusion

Notebook manufacturing blends material science with precise engineering. From bamboo pulping to spiral binding, each step impacts functionality. Partnering with specialized factories ensures quality and sustainability.

Ready to create your perfect notebook?

Email Timothy@notebookring.com for:

✅ Free material sample kit (20+ options)

✅ DFM analysis report

✅ 5% discount on first order

We make stationery engineering simple.

-

Explore this link to understand the intricate processes and technologies that make notebook manufacturing efficient and innovative. ↩