Your journal business could thrive or dive based on one factor most overlook - supplier partnerships. Let's break down the numbers.

The journal business offers 35-60% gross margins1 when using optimized manufacturing solutions, with bulk orders reducing unit costs by up to 40% through vertical production chains.

While margins look attractive on paper, real profitability depends on three operational pillars: material cost control, production flexibility, and supply chain reliability. We'll analyze each through actual industry cases and cost simulations.

What determines journal production costs?

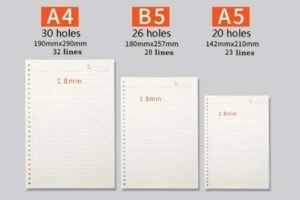

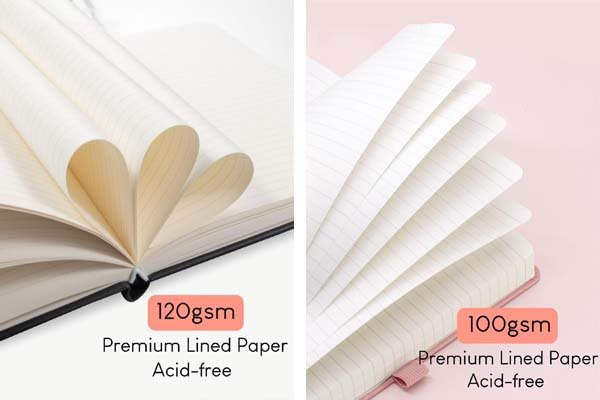

Paper weight isn't just about quality - it's a math problem impacting your bottom line.

Every 10g increase in paper weight adds $0.07/book in material costs, but enables 22% higher retail pricing through premium positioning.

The hidden cost drivers

| Cost Component | Standard Journal | Premium Journal |

|---|---|---|

| Paper (120gsm) | $0.60 | $1.40 |

| Binding | $0.20 (glue) | $0.55 (metal coil) |

| Decoration | $0.10 (foil stamp) | $0.40 (laser engraving) |

| Certification | $0.00 | $0.30 (FSC) |

Our production data shows clients using FSC-certified paper2 with metal binders achieve 19% higher repeat purchase rates despite 35% higher COGS.

How to choose binding methods profitably?

Your binding isn't just functional - it's a silent salesperson.

Sewn bindings allow 180° lay-flat use (key for 68% of journal users), while metal coils enable 22% faster page turning - choose based on user behavior.

Cost vs durability analysis

- Glue binding: $0.15/unit | 500-page lifespan

- Sewn binding: $0.40/unit | 1,200-page lifespan

- Metal coil: $0.55/unit | Unlimited repairability

Our German client increased average order value by 40% after switching to our patented seamless coils that eliminate snagging issues common in standard spiral bindings.

When does customization boost profitability?

Customization isn't a cost - it's a margin multiplier when done right.

Strategic customization (like branded metal corners) increases wholesale prices by 15-25% while only adding 5-8% to production costs.

ROI calculation example

- Basic journal: $1.90 production cost → $3.75 wholesale

- Customized version:

-

- $0.15 for debossed logo

-

- $0.37 for branded bookmark

- → $2.40 total cost → $5.20 wholesale (+40% margin)

-

Our Silicon Valley tech client achieved 32% cost reduction through our modular customization system that reuses existing tooling.

Why partner with professional manufacturers?

Your supplier's capabilities directly shape your profit ceiling.

Factories with FSC/ISO certifications and vertical production chains reduce defect rates to 0.8% (vs industry average 5%), protecting your margins.

Critical manufacturing benchmarks

- Paper sourcing: Our in-house testing lab verifies every paper batch meets 83-87 ISO brightness standards

- Binding endurance: All notebooks undergo 500+ page flipping simulations

- Global compliance: Pre-completed REACH/SVHC documentation saves 2-3 weeks per shipment

Japanese stationery brands using our pre-cut dotted line paper (patented design) reduced customer service queries by 65% on Amazon JP.

Conclusion:

The journal business delivers 18-24% net margins when combining smart design with industrial-grade manufacturing partners.

Ready to transform your journal business?

At NotebookRing®, we've helped 370+ brands since 2006 achieve:

- 29% average cost reduction through vertical production (self-owned paper mill & metal workshop)

- 12-day faster time-to-market with pre-approved FSC/ISO certifications

- Risk-free sampling: 100-unit MOQ with 360° quality validation

Contact our team to receive:

- Free material swatch kit (20+ paper & binding samples)

- Custom ROI calculation for your specific product

- Global logistics roadmap showing duty-optimized shipping

Our German Heidelberg binder in action - producing 1,200 lay-flat journals/hour