Do you wonder how those notebooks you love get made? It might seem like a complex process with so many choices. But understanding the basics can help you create the perfect notebook for your needs.

Making a notebook involves designing the cover and pages, choosing the right materials like paper and cover stock, printing everything, binding the pages together, and adding any finishing touches.

So, the journey of a notebook starts long before it reaches your hands. It begins with an idea, maybe a specific purpose like journaling, sketching, or corporate branding. From that idea, we move into the practical steps of creation. It's a mix of design choices and manufacturing processes. We need to think about how it looks, feels, and functions.

Breaking it down, the main parts are the cover and the inside pages, often called the 'book block'. How these two parts are designed, the materials used for them, and how they are joined together define the final product. Each step offers chances for customization, which is something we handle every day here at NotebookRing®. [Brief personal anecdote about seeing a simple idea turn into a finished notebook].

What Are the Key Steps in Notebook Production?

Getting into the details, what exactly happens at the factory level? Let's look at the main stages.

The key production steps are pre-press (finalizing designs), printing the covers and inner pages, binding them together using methods like sewing or coiling, finishing (like trimming), and crucial quality control checks throughout.

Understanding the Production Flow

Bringing a notebook to life involves several precise steps. I've seen this process thousands of times since we started back in 2006, and while technology evolves, the core stages remain vital.

Pre-press Preparation

This is the digital groundwork. Before anything hits the printing press, designs need to be finalized and checked. We make sure the artwork for the cover is correct, and the layout for the inner pages (lines, grids, dots, or blank) is exactly as specified. We prepare printing plates or digital files, ensuring colors and dimensions are accurate. It’s like checking the blueprint before building a house – crucial to get right.

The Printing Process

Next comes printing. Covers often get special treatment – maybe full-color printing, or specific techniques like hot stamping or embossing that we offer. Inner pages are usually printed in large sheets. The choice of paper (like 80gsm, 100gsm, or even special types like recycled paper) affects the look and feel. We use reliable machines, like our German Heidelberg presses, to ensure consistency.

Binding It All Together

This is where the loose pages become a notebook. There are several ways to bind:

| Binding Method | Description | Best For | Considerations |

|---|---|---|---|

| Sewn Glue Binding | Pages are sewn in sections, then glued to spine | Journals, high-quality books, lay-flat | Can be more costly |

| Spiral/Coil Binding | Wire or plastic coil loops through punched holes | Planners, workbooks, 360° folding | Coil can sometimes snag (ours don't!) |

| Metal Ring Binders | Loose pages fit onto metal rings in a binder | Refillable organizers, flexible systems | Bulkier than other types |

| Saddle Stitch | Pages folded and stapled through the spine | Thin booklets, simple notebooks | Limited page count |

We even developed a patented "seamless coil" to avoid snagging – small innovations matter! Choosing the right binding depends on how the notebook will be used.

Finishing Touches

The notebook is almost ready. Large printed sheets are cut down to the final size. Corners might be rounded. Extras like elastic closures, ribbon bookmarks, or pockets can be added here. It's these details that often elevate a standard notebook into something special.

Quality Control – Non-Negotiable

Finally, every notebook needs checking. At NotebookRing®, we have a 4-level quality inspection process. We check paper weight, binding strength (we test page turns!), look for printing errors, and even test how the notebooks hold up during shipping. This ensures the final product meets the high standards our clients expect, whether they're in Europe, the US, or Japan.

How Can I Customize My Notebook Design?

Want something unique? Customization is where you can really make a notebook your own, or perfectly fit your brand.

You can customize almost everything: the cover material and design (printing, hot stamping, embossing), the inner page paper type, weight, and ruling (lines, dots, grid), the binding method and color, the overall size and shape, and adding accessories.

Exploring Customization Options

Customization is at the heart of what we do. It allows clients like Sarah from the German bookstore chain or James from the Singapore gift company to get exactly what they need. Let's look at the key areas:

Cover Customization

The cover is the first impression. Your options are huge:

- Materials: PU leather, fabric, cardstock, Kraft paper, even eco-friendly options like bagasse fiber or degradable PP.

- Branding/Design:

- Printing: Full color, specific Pantone colors.

- Hot Stamping: Adds metallic or colored foil designs (~$0.08/unit extra).

- Embossing/Debossing: Creates a raised or indented effect (~$0.15/unit extra).

- Laser Engraving: Etches designs onto surfaces like metal or wood (~$0.12/unit extra).

- Cloth Hardcovers: A classic, durable choice.

Inner Page Personalization

The inside matters just as much:

- Paper Type: Choose from standard acid-free paper, recycled paper (no extra cost for this option!), premium Japanese Tomoe River paper, or European sketch paper.

- Paper Weight: Common weights are 80gsm, 100gsm, or 120gsm. Upgrading from 80gsm to 100gsm adds about $0.07 per book typically.

- Ruling/Format: Lined, grid, dotted, blank are standard. We can also print custom layouts, page numbers, or logos on each page.

- Other Details: Options like perforated pages for easy tearing or rounded corners.

Binding, Size, and Shape

- Binding: Choose the method (sewn, coil, binder mechanism) that suits the notebook's use. We can even customize coil colors.

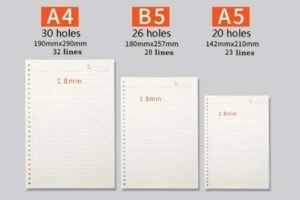

- Size: Standard sizes like A5, B5, B6 are common, but we can create custom dimensions or even special shapes (die-cutting).

- Compatibility: For binder systems, we ensure compatibility with standards like Filofax (6-hole) or Campus (20/26-hole).

Eco-Friendly Choices

Many clients prioritize sustainability, like our German bookstore partner needing FSC certification. We offer:

- FSC™ Certified Paper: Guarantees paper comes from responsibly managed forests (our cert: C106904).

- Recycled Paper: Reduces waste.

- Soy Ink: A more environmentally friendly printing option.

- Sustainable Covers: Like bagasse (sugarcane waste) or degradable plastics.

- We even track our carbon footprint and plant trees for sales!

Why Partner with NotebookRing® for Your Custom Notebooks?

So, you know how notebooks are made and customized. But choosing the right manufacturing partner is key. Making notebooks since 2006 has taught me a lot, and I believe our approach at NotebookRing® offers real advantages.

We're not just assemblers; we have a vertically integrated production chain, including our own paper processing and metal stamping workshops. This gives us tight control over quality and costs, from raw materials to the finished product. Our notebooks typically cost between $0.84-$1.70 for 1,000+ units, or $0.63-$1.30 for 10,000+ units, before specific customizations.

Flexibility is important. Whether you need a small sample run of 100 basic notebooks or large batches of 500+, we can handle it. This helps businesses like James Wong's gift company that need smaller, regular orders.

We blend traditional craftsmanship with innovation, like our patented seamless coil binding. Quality is paramount, backed by ISO 9001, FSC™, and BSCI certifications, plus our rigorous 4-level internal checks meeting standards like REACH/SVHC and ISTA 3A.

And we're committed to sustainability, offering eco-friendly materials and contributing to reforestation. We've helped clients like a major German bookstore create successful FSC-certified series and a Silicon Valley tech company develop sustainable onboarding kits while saving costs.

If you're looking for a reliable partner for custom notebooks or binders, I invite you to reach out. We offer free physical sample books with material swatches and can provide detailed OEM proposals within 24 hours. Let's discuss how we can bring your notebook idea to life. You can contact us via info@notebookring.com or visit www.notebookring.com.

Conclusion: Bringing Your Notebook Idea to Life

Making a notebook involves careful planning in design, materials, printing, and binding, followed by strict quality checks. Customization offers endless possibilities, and partnering with an experienced manufacturer makes the whole process smooth and successful.