Page count is one of the most frequently asked questions from notebook buyers—and also one of the most customizable elements in notebook production. Experienced manufacturers can offer flexible page ranges from 50 to over 200 pages, depending on client needs.

NotebookRing®, with over 18 years of manufacturing experience, notes that page count affects not just a notebook’s purpose but also its pricing and user experience. Their production system supports diverse formats efficiently, serving clients such as German bookstores and Silicon Valley companies.

With a vertically integrated production chain, from raw paper to final binding, the company can easily adjust page count1s. Whether it's 50-page tear-resistant notebooks for schools or 120-page sketchbooks for creatives, the system supports a range of requests starting from just 500 units.

Can Custom Page Counts Be Ordered?

Yes. Fully customizable page counts2 are available, from under 50 pages to over 200 pages. Minimum order quantity (MOQ) for custom runs starts at 500 units.

This flexibility supports unique product formats that don’t fit standard sizes. Examples include custom planners3 for corporate gifting and minimalist weekly planners for lifestyle brands.

Customization Workflow

- The client provides a preferred page count.

- The manufacturer suggests suitable paper weight4 and binding style.

- Final adjustments are made to ensure performance and user comfort.

Binding types vary by thickness—for example, sewn glue binding for high page counts or seamless coil for slimmer notebooks.

Customization Tiers and MOQ

| Customization Tier | MOQ | Page Count Range | Typical Uses |

|---|---|---|---|

| Sample Order | 100 units | Standard options | Testing materials and print quality |

| Basic Custom Batch | 500+ units | 50–240 pages | Startups, business gifts, short-run projects |

| Full-Scale Production | 10,000+ units | Any feasible | Retail chains, mass-market product lines |

For example, a corporate gift supplier in Singapore regularly places 300-unit monthly orders requiring precise page counts.

Are 96, 120, and 200-Page Notebooks Available?

Yes. These page counts are standard options and are optimized for mass production.

96 Pages: Balanced Utility

- Use Cases: General note-taking, school, daily journaling

- Binding: Metal coil or sewn glue

- Example: Educational clients often choose this size for branded student notebooks.

120 Pages: Mid-Premium Range

- Use Cases: Professional planners, upscale journals

- Paper Upgrade Option: From 80gsm to 100gsm (~$0.07 per book)

- Example: Used by tech companies in employee onboarding kits with custom planning layouts.

200 Pages: High-Capacity Format

- Use Cases: Writers, sketch artists, annual planners

- Binding Note: Requires advanced binding like lay-flat or bare-spine methods

- Example: Japanese stationery brands use Tomoe River paper to keep thickness below 8mm even at high page counts.

What Matters More: Page Count or Thickness?

It depends on the audience:

- Consumers often evaluate notebooks by thickness.

- Product teams prioritize page count for content planning.

Factors That Influence Thickness

- Paper Weight: Moving from 80gsm to 100gsm or 120gsm adds bulk.

- Cover Type: Hardcover or layered covers can increase perceived value.

When Page Count Is Critical

For content-driven products—like planners or educational notebooks—precise page counts are essential. For instance, a German bookstore chain required specific sections with classified pages, which were delivered through tailored printing and binding.

Does Page Count Affect Shipping Costs?

Yes. More pages increase both weight and volume, which raises shipping costs5.

Sample Shipment Weights (A5, 80gsm)

| Page Count | Paper Weight | Single Book | 5,000-Unit Shipment |

|---|---|---|---|

| 96 pages | 80gsm | 150g | 750 kg (1,653 lbs) |

| 120 pages | 80gsm | 180g | 900 kg (1,984 lbs) |

| 200 pages | 80gsm | 280g | 1,400 kg (3,086 lbs) |

| 120 pages | 100gsm | 220g | 1,100 kg (2,425 lbs) |

Cost-Saving Shipping Strategies

- Packaging Optimization: Custom master cartons maximize load efficiency.

- Logistics Support: Support for EXW, FOB, and DDP incoterms.

- Inventory Services: Optional bonded storage in China for flexible international shipments.

Using Page Count for Product Differentiation

Page count and thickness can differentiate product lines across price tiers or user needs.

Good-Better-Best Tiering Model

- Good: 96 pages, 80gsm, softcover – basic, budget-friendly

- Better: 120 pages, 100gsm, hardcover, bookmark ribbon

- Best: 200 pages, 120gsm sketch paper, lay-flat binding, premium finishes6

Niche-Driven Development

- For Travelers: Thin 64-page pocket-sized planners

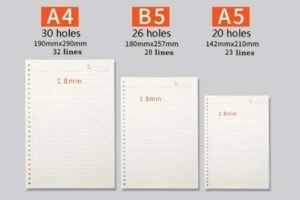

- For Artists: B5 200-page sketchbooks with 120gsm acid-free paper

- For Planners: Journals with tailored 6- or 18-month calendars

Manufacturing Support

NotebookRing® provides a free sample book with over 20 types of paper and material swatches. Their team helps match page count1, paper quality, and binding style to target user expectations and market positioning.

Conclusion

Page count is a crucial factor in notebook design. It influences usability, appearance, and logistics. Experienced manufacturers offer customizable options with low MOQs and support services, allowing brands to balance product function with production cost.

-

Understanding page count helps you choose the right notebook for your needs, enhancing usability and satisfaction. ↩ ↩

-

Explore how customizable options can meet specific needs and enhance user experience. ↩

-

Explore the advantages of custom planners for businesses looking to make a lasting impression. ↩

-

Understanding paper weight can help you choose notebooks that meet your thickness preferences. ↩

-

Find out how page count influences shipping expenses, which is crucial for budgeting. ↩

-

Explore how premium finishes can enhance the appeal and value of your notebooks. ↩