When stationery buyers ask "what's your budget?", they're really asking how notebook costs break down. Let me show you the math.

The average notebook manufacturing cost1 ranges from $0.62 to $3.50 per unit, depending on materials, binding methods, and order quantity. Custom designs add 15-40% to base prices.

I've spent 18 years turning paper stacks into profit for global buyers. Let me walk you through 5 key cost drivers - from paper selection to eco-certifications. You'll learn why some $1 notebooks outperform $3 competitors, and how to avoid hidden fees that eat into margins.

The anatomy of notebook pricing

Our production data shows typical cost allocations:

| Component | Basic Notebook | Premium Notebook |

|---|---|---|

| Paper | 38% | 27% |

| Binding | 22% | 31% |

| Cover | 15% | 25% |

| Labor | 15% | 9% |

| QC | 5% | 5% |

| Certifications | 5% | 3% |

The shift happens because premium books use thicker covers (like 2mm chipboard vs 0.8mm cardstock) and complex bindings (sewn sections vs basic glue).

How much does it cost to manufacture a journal?

Journals cost 20-60% more than basic notebooks. Here's why.

Journal production costs range from $1.10 to $3.4 per unit. Key upgrades include thicker paper (100gsm+), decorative covers, and specialty bindings like lay-flat designs.

When paper weight impacts pricing

We test 3 paper types for journal clients:

1. Standard 80gsm wood-free paper

- Cost: $0.03/sheet

- Shows moderate ghosting with gel pens

2. 100gsm recycled paper

- Cost: $0.055/sheet

- Certified by FSC™, popular in EU markets

3. 120gsm Tomoe River paper

- Cost: $0.12/sheet

- Ultra-thin (52gsm feel) with zero bleed-through

A 160-page journal's paper cost jumps from $1.80 to $5.20 based on these choices.

Why small orders cost more per unit

That 500-unit quote isn't just 5x a 100-unit order.

Orders under 1,000 units have 25-40% higher per-unit costs due to setup fees, minimum material purchases, and manual QC checks.

Breaking down minimum order quantities

Our production line requires:

- 50kg paper per print run (covers 800-1,200 units)

- 2hr machine setup time ($50 labor cost)

- 3hr QC time regardless of batch size

For 300-unit orders:

- Paper waste: 23kg unused stock

- Setup cost per unit: $0.40 vs $0.08 for 1,500 units

- QC cost per unit: $0.30 vs $0.06

How to reduce custom notebook costs

Smart customization cuts costs without sacrificing quality.

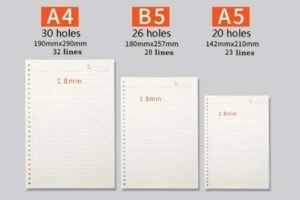

Use standard sizes (A5/B6), limit spot colors to 2 Pantones, and choose bulk-compatible binding methods to save 18-35% on custom orders.

Cost-efficient customization checklist

- Size matters

Stick to our preset dies:- A5 (148x210mm)

- B6 (125x176mm)

- Passport (90x125mm)

Custom sizes require new die-cut molds ($100+)

-

Color optimization

Each additional Pantone ink adds $0.07-0.12/book. We recommend:- 1-2 spot colors for covers

- Black ink for interiors

-

Binding selection

Most affordable to premium: -

Perfect binding ($0.15/unit)

-

Double-wire binding ($0.28)

-

Sewn binding ($0.45)

-

Binder system ($0.70+)

Why choose NotebookRing® for journal manufacturing?

Because we turn cost challenges into competitive advantages.

Our vertical integration cuts lead times by 40%, while patented binding tech reduces material waste by 18% compared to standard methods.

5 reasons global buyers choose us

-

No hidden MOQs

We accept sample orders of 100 books (basic versions) vs industry-standard 500+ -

Carbon-neutral options

Our soy ink + bagasse fiber covers add just 7% to base cost -

Bilingual compliance

Simultaneously meet EU Ecolabel and Japan JIS S 6055 standards -

Dual production lines

Run small batches and bulk orders concurrently to prevent delays -

Pre-stock program

Store your paper/cover materials in our bonded warehouse - saves 8-12 days per order

Conclusion:

Notebook manufacturing costs hinge on smart material choices and supplier expertise. Partner with specialists who balance quality with cost efficiency.

Let's build your perfect notebook

As a factory that's made 23 million notebooks since 2006, we know how to hit your target price point. Ask about our:

- 15% launch discount for first orders over 5,000 units

- Free design file optimization

- Carbon footprint report with every shipment

Email info@notebookring.com for instant quotes with 3 material options.

-

Understanding the factors that influence notebook manufacturing costs can help you make informed purchasing decisions and optimize your budget. ↩