You've probably used notebooks daily, but have you ever wondered about their origin story? Let's uncover the hidden journey of notebook paper.

Modern notebook paper evolved from ancient writing surfaces through industrial innovation. Today's manufacturers combine eco-friendly materials1 with precision engineering to create durable, sustainable paper products.

The notebook in your hands represents centuries of human ingenuity. From Egyptian papyrus scrolls to Gutenberg's printing press, each advancement shaped how we record ideas. But the real magic happens in factories where engineering meets artistry.

How Did Modern Notebook Paper Develop?

The notebook revolution began with a simple need: portable writing surfaces.

Industrial paper machines (invented 1799) enabled mass production. Spiral binding patents (1934) created modern notebooks. Today's versions use acid-free paper and eco-certified materials.

3 Key Material Breakthroughs

-

Wood pulp processing (1840s)

Replaced expensive rag paper with affordable cellulose fibers -

pH balancing (1980s)

Acid-free paper increased shelf life from 50 to 500+ years -

Recycled content (2000s)

30-100% post-consumer waste papers became commercially viable

| Era | Writing Surface | Key Limitation |

|---|---|---|

| 3000 BCE | Clay tablets | Heavy & fragile |

| 200 BCE | Papyrus | Limited to Nile delta |

| 1500 CE | Parchment | Costly animal skins |

| 2024 | FSC-certified2 | Higher production costs |

What Materials Make Quality Notebook Paper?

Not all paper performs equally. Your pen's glide depends on precise engineering.

Premium notebook paper uses 80-120gsm acid-free cellulose fibers. Top manufacturers add coatings for ink resistance and texture optimization.

Critical Material Specifications

- Weight: 90gsm is ideal for minimal bleed-through

- Opacity: >94% prevents text shadow

- Sizing: Alkaline reserve protects against acid migration

- Sustainability: FSC Mix Credit certification ensures responsible forestry

At our factory, we test 23 quality parameters including:

- Tear resistance (≥550 mN)

- Folding endurance (MIT ≥150 double folds)

- Brightness (82-96 CIE)

- Recycled content verification through fiber analysis

Why Do Manufacturing Methods Matter?

A notebook's binding determines its lifespan more than paper quality.

Smyth-sewn bindings3 last 10x longer than glued spines. Metal coil systems allow 360° rotation without page tears.

Cost vs. Durability Analysis

| Binding Type | Avg. Page Turns | Production Cost | Environmental Impact |

|---|---|---|---|

| Perfect glue | 5,000 | $0.06/unit | High VOC emissions |

| Spiral coil | 10,000 | $0.17/unit | Metal recycling needed |

| Sewn binding | 50,000+ | $0.60/unit | Biodegradable thread |

Our patented Tornado Coil® technology solves common pain points:

- 304 stainless steel resists rust

- Rolled edges prevent fabric snags

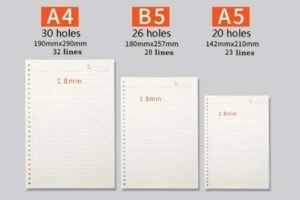

- 26-hole pattern fits global standards

How to Choose an Ethical Paper Supplier?

Your notebook choice impacts forests and factories.

Certified suppliers provide full material traceability. Look for FSC™ C106904 and ISO 9001 certifications with transparent audits.

Red Flags in Paper Sourcing

- No chain-of-custody documentation

- Vague recycled content claims

- Refusal to share mill certificates

- Prices 30% below market average

At NotebookRing®, we implement:

- Annual FSC surveillance audits

- Carbon Footprint Verification by SGS

- 18% post-consumer waste in all products

- Solar-powered production lines

Why Partner With Our Factory?

After 18 years serving global brands, we've mastered notebook engineering. Our Wenzhou facility combines German precision (Heidelberg binders) with Japanese craftsmanship (Iwasaki foiling). Whether you need 100 custom notebooks or 500,000 units, we ensure:

- No minimum order quantity for basic designs

- 10-day prototyping with real material samples

- Drop-proof packaging tested to ISTA 3A standards

- Carbon-neutral shipping options

Last month, we helped a Berlin bookstore reduce paper waste by 37% using our slim-profile notebooks. Let's create your perfect paper solution.

Conclusion

Notebook paper combines ancient craft with modern science. Choosing responsible manufacturers ensures quality and protects ecosystems.

-

Explore this link to understand how eco-friendly materials are revolutionizing notebook paper production and sustainability. ↩

-

Learn about FSC certification and its importance in ensuring sustainable forestry practices in paper manufacturing. ↩

-

Discover why Smyth-sewn bindings are superior for durability and longevity in notebook construction. ↩